High Quality Products

Flexible Response

Sanko Electric responds to various range of applications from only substrate to complete unit OEM production with its business based on EMS business, harness business, and electrical materials as the 3 cores business.

Participation in designs stage in customers enables us to contribute to total cost reduction aggressively.

OUR BUSINESS

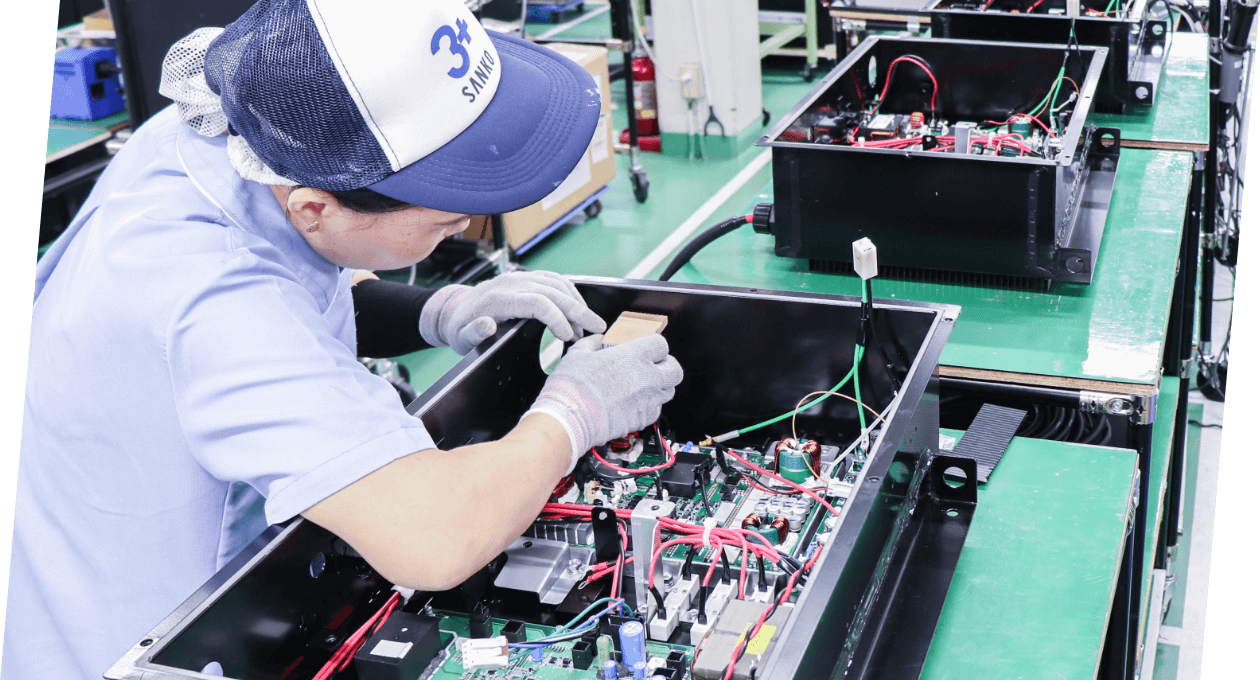

EMS BUSINESS

Develop its business to industrial equipment manufacturers, transport equipment manufacturers, and housing equipment manufacturers including automobile manufacturers spreading its wing.

Our flexible response and high quality are willingly appreciated.

Responds to various range of applications from only substrate to complete unit OEM production with its business.

Participation in designs stage in customers enables us to contribute to total cost reduction aggressively.

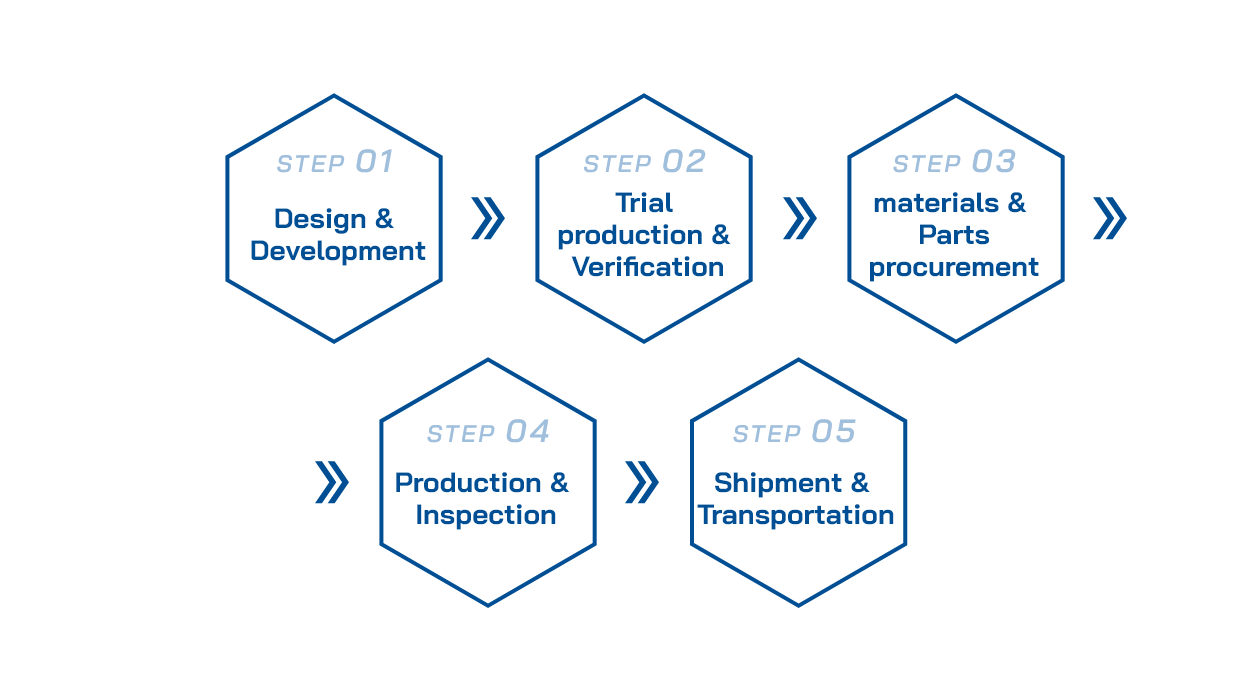

Realize one-stop service to

respond to high-quality production.

Respond to customers’ requirements by the consistent services from design & development to the inspection, shipment & transportation through trial production & verification, materials & parts procurement with its high quality.

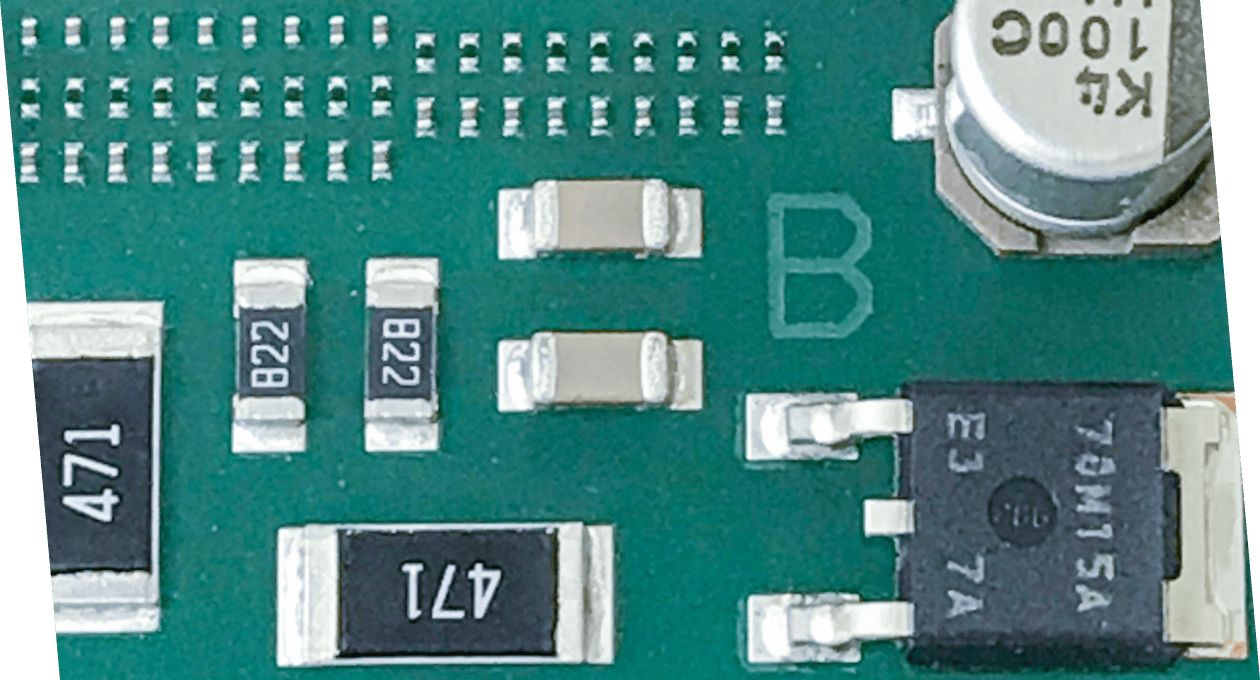

Circuit board production the latest facilities

Introduced the latest equipment such as the new mounting machine (YAMAHA) and 3D image inspection machine (equipped with AI learning function) to establish a system so as to enable high-quality production.

High-density mounting

Equipped facilities to respond to miniaturization of electronic units and devices as well.

Those are also available to respond to miniature-seized parts mounting such as 0603 and BGA typed package.

Unit assembly

Available to produce variety of ranges from large-sized control boxes to small-sized controller and units in combination with our in-house mounting boards and harnesses.

Birth on-site + Grow-up on-site + Smart tools for the site

Progress recognition, management, time counting, plan change etc. Perform an operation on problems at the manufacturing site !!

Promotion to makesmart factory

We also introduced 3+ in each production process and succeeded in visualizing various information such as production progress, actual production time, and in-process defects.

HARNESS BUSINESS

Respond to every application to require harness from automotive application to industrial equipment application.

Realize the same quality with the same production process in the world regardless of domestic sales or overseas sales.

Domestic production

- ・Harnesses for domestic use

- Harness for industrial equipment and cold apparatus

- ・In-house assembly harness

- Harnesses production for in-house use

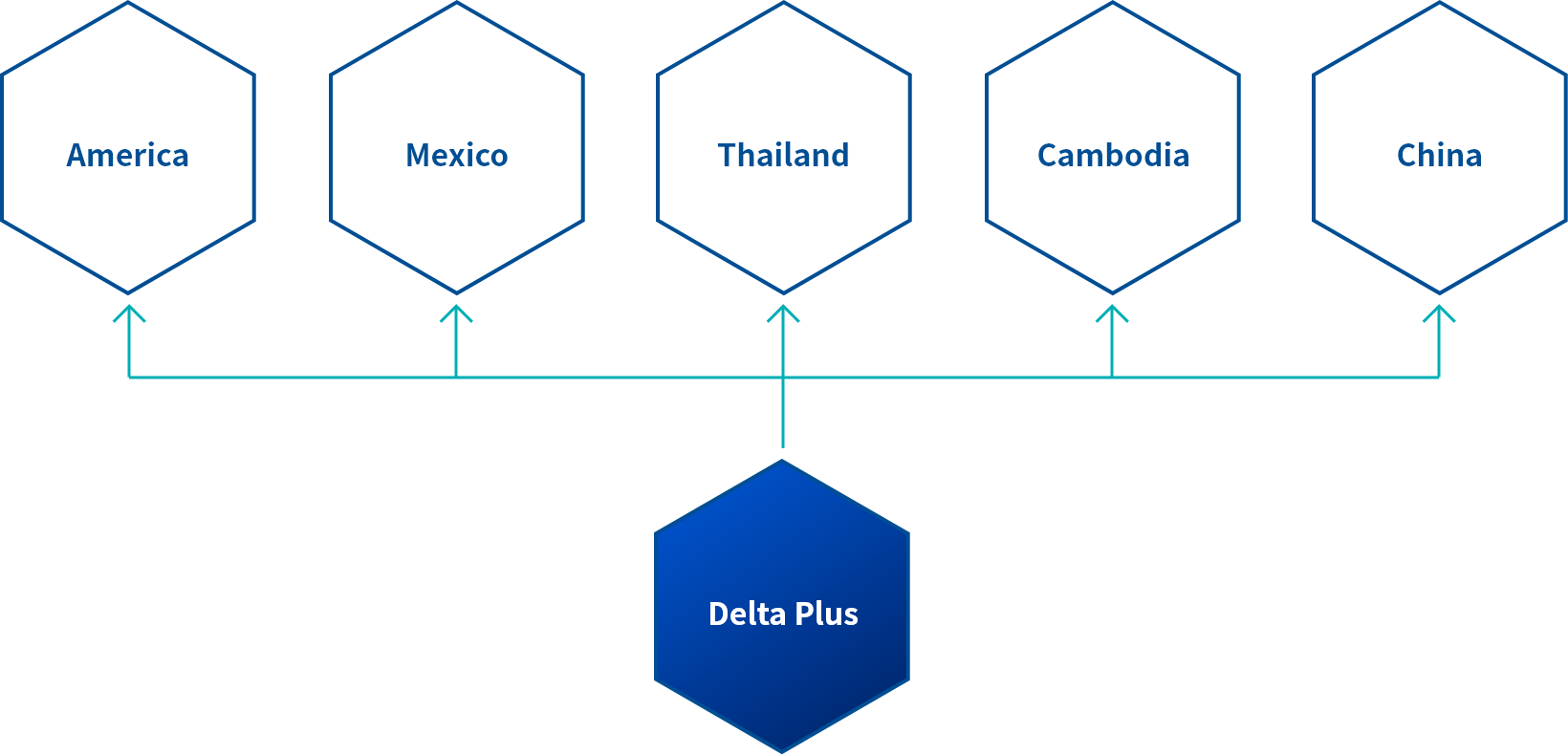

Overseas production

Overseas production bases produce harnesses mainly used for automotive application.

Delta Plus as the mother factory to support overseas production bases is responsible for the technical support including process designs, production method reviews, equipment arrangements, setups on-sites, and workers & managers training.

Mother factory for wire harness processing

Technical and quality support for harness processed in the overseas factories